How Savor churned butter from thin air

How does Savor produce a butter-like product without relying on any animal or plant-based ingredients? While the company isn't revealing its proprietary methods, there is a general understanding of their approach. Savor employs a unique thermochemical process that enables the creation of fat molecules from scratch using three elements found in the air: carbon dioxide, hydrogen, and oxygen.

The process begins with carbon dioxide, which can be captured from the atmosphere or sourced from traditional CO2-emitting activities, such as municipal waste. This carbon dioxide is then combined with hydrogen through a chemical reaction known as the Fischer-Tropsch process, resulting in the formation of hydrocarbon chains. These hydrocarbons are subsequently oxidized to produce fatty acids. Finally, the fatty acids are "enhanced" with various additives to create a product that resembles and tastes like butter: a bit of water for moisture, an emulsifying agent, beta-carotene for a more natural hue, and — interestingly — a hint of rosemary oil for added flavor.

Thus, Savor has developed a butter-like spread derived from CO2, entirely free of animal or plant ingredients. While the company keeps the precise details confidential, they are confident enough in their product to invite taste testers, and early feedback has been overwhelmingly positive.

Non-dairy fats can help save the planet

Savor generated significant buzz in the scientific community with the announcement of its groundbreaking innovation. The creation of fats without the use of living organisms is seen as a crucial element in achieving a carbon-free future. If Savor can successfully scale up its production, it could lead to a decrease in livestock farming and, consequently, a reduction in their substantial carbon emissions.

The statistics Savor provided about their CO2 butter are particularly impressive. Their butter boasts a carbon footprint of under 0.8 grams of CO2 equivalent per calorie, which is less than half the environmental impact of conventional butter, which averages around 2.4 grams. The contrast with plant-based alternatives is even more pronounced. Savor's method requires only one-thousandth of the water needed for cultivating oil crops and occupies no land—just a well-equipped laboratory is sufficient.

Savor's ambitions extend beyond butter. They have plans to produce CO2-based milk, ice cream, cheese, and plant-free cooking oils using the same innovative process. Can the company fulfill these aspirations? Only time will tell. For now, the outlook is certainly promising, and we can't wait to try making a compound butter for our steaks with CO2 butter!

Recommended

Is Tilapia Really A Garbage Fish?

Why Couscous Doesn't Actually Count As A Grain

3 Misconceptions You Shouldn't Believe About The Labels On Your Bread

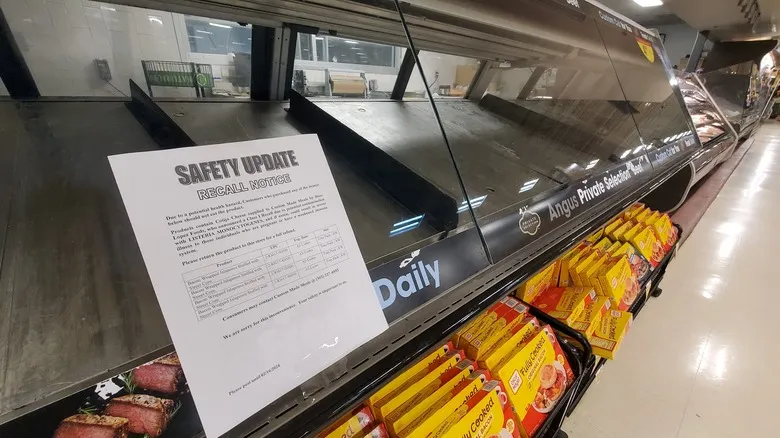

Here's The Safest Way To Dispose Of Recalled Foods

Next up